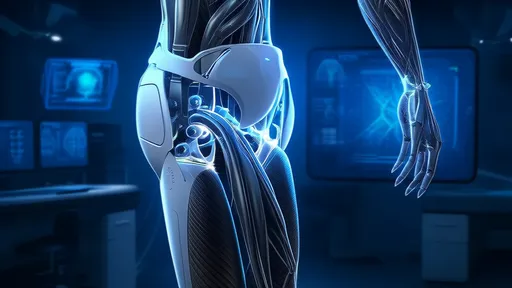

The field of medical prosthetics is on the verge of a paradigm shift, as researchers unveil a groundbreaking technology that could render traditional joint replacements obsolete. Magnetic nanofluid bearings, a concept borrowed from aerospace engineering, are now being adapted to create artificial joints that promise to eliminate friction entirely. This innovation could dramatically improve the quality of life for millions suffering from arthritis and joint degeneration.

At the heart of this technology lies a sophisticated interplay between magnetic fields and nanoparticle suspensions. Unlike conventional bearings that rely on physical contact between metal or ceramic components, these new systems suspend the joint surfaces in a magnetic fluid that maintains perfect alignment while allowing free rotation. The result is a joint that theoretically never wears out, as there's no mechanical contact to cause deterioration over time.

How Magnetic Nanofluid Bearings Work

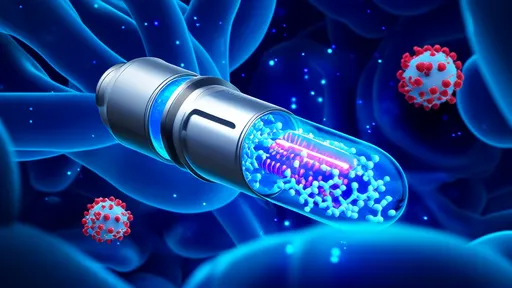

The system utilizes a specialized ferrofluid containing suspended iron oxide nanoparticles, typically 10-20 nanometers in diameter. These particles become magnetized when exposed to a magnetic field, creating a stable, pressure-resistant fluid matrix. The artificial joint components are embedded with precisely arranged permanent magnets that create a magnetic field geometry capable of supporting physiological loads while maintaining a consistent fluid gap of about 100 micrometers between surfaces.

What makes this technology particularly remarkable is its self-healing properties. If the joint experiences sudden impact or unusual loading patterns, the magnetic field instantly redistributes the nanoparticles to maintain optimal spacing and lubrication. This dynamic responsiveness mimics the adaptive qualities of natural synovial joints far better than any rigid mechanical prosthesis currently available.

Clinical Advantages Over Conventional Implants

Traditional joint replacements face inevitable wear from friction, generating particulate debris that often leads to osteolysis (bone dissolution) and eventual implant failure. Magnetic nanofluid bearings produce no such wear particles, potentially extending implant longevity indefinitely. Patients could avoid the multiple revision surgeries that currently plague joint replacement therapy, especially in younger, more active individuals.

Another significant benefit is the complete elimination of prosthetic joint squeaking - a surprisingly common complaint with ceramic-on-ceramic implants. The fluid interface operates silently, restoring natural quiet movement. Early studies also suggest the technology may reduce inflammation markers compared to conventional implants, possibly due to the absence of constant micro-abrasion at the bearing surfaces.

Engineering Challenges and Solutions

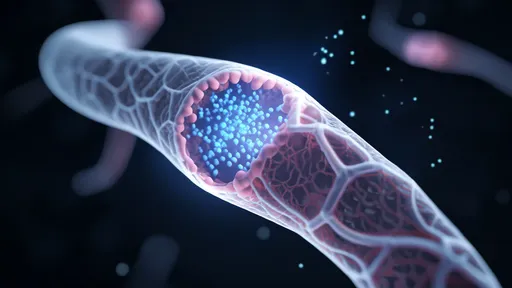

Developing clinically viable magnetic bearings required solving several formidable technical problems. The first major hurdle was creating a biocompatible ferrofluid that wouldn't break down in the body's ionic environment. Researchers achieved this by developing novel nanoparticle coatings using medical-grade polymers that resist protein adsorption and maintain colloidal stability in physiological fluids.

Another challenge involved ensuring the magnetic field strength remained sufficient to support body weight without requiring impractical amounts of magnetic material. The solution came from optimizing Halbach array configurations in the implant magnets - a special arrangement that amplifies the field on one side while canceling it on the other. This allows strong support where needed while minimizing stray fields that could affect surrounding tissues or medical devices.

Current Status and Future Prospects

After successful animal trials demonstrating 18 months of flawless operation in load-bearing joints, human clinical trials are scheduled to begin next year. The first applications will target hip replacements, where the technology's weight-bearing capabilities can be thoroughly evaluated. If successful, the platform could expand to knees, shoulders, and even spinal disc replacements.

Looking further ahead, researchers envision incorporating smart capabilities into these bearings. By adding sensor nanoparticles to the fluid, doctors could remotely monitor joint loading patterns, detect early signs of loosening, or even adjust magnetic field parameters to accommodate changing patient needs - all without additional surgeries.

While cost remains higher than conventional implants, analysts predict price parity within a decade as manufacturing scales up. The potential savings from eliminating revision surgeries could make this technology economically transformative for healthcare systems worldwide. As one lead researcher remarked, "We're not just improving joint replacements - we're redefining what artificial joints can be."

The advent of magnetic nanofluid bearings represents more than just another incremental advance in medical technology. It offers a glimpse into a future where mechanical wear becomes irrelevant to prosthetic design, where joints might last a lifetime regardless of patient activity levels, and where the very concept of a "worn out" artificial joint becomes a historical footnote in medical textbooks.

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025